Table of Contents

- 0.1 The Six Sigma Approach to Marketing Agency Excellence

- 0.2 What is Six Sigma?

- 0.3 How is Six Sigma different from the EOS approach to improvement?

- 0.4 What is Lean Six Sigma?

- 0.5 What are the belts in six sigma?

- 0.6 The definitive guide to implementing Six Sigma into your agency business:

- 0.6.1 To help teams define and standardize processes, here are some key strategies:

- 0.6.2 To help teams map the customer journey, here are some key strategies:

- 0.6.3 Teams can identify waste in their processes by following these steps:

- 0.6.4 Here is a framework for conducting Root Cause Analysis (RCA):

- 0.6.5 Plan-Do-Check-Act (PDCA) Methodology to Solving Problems

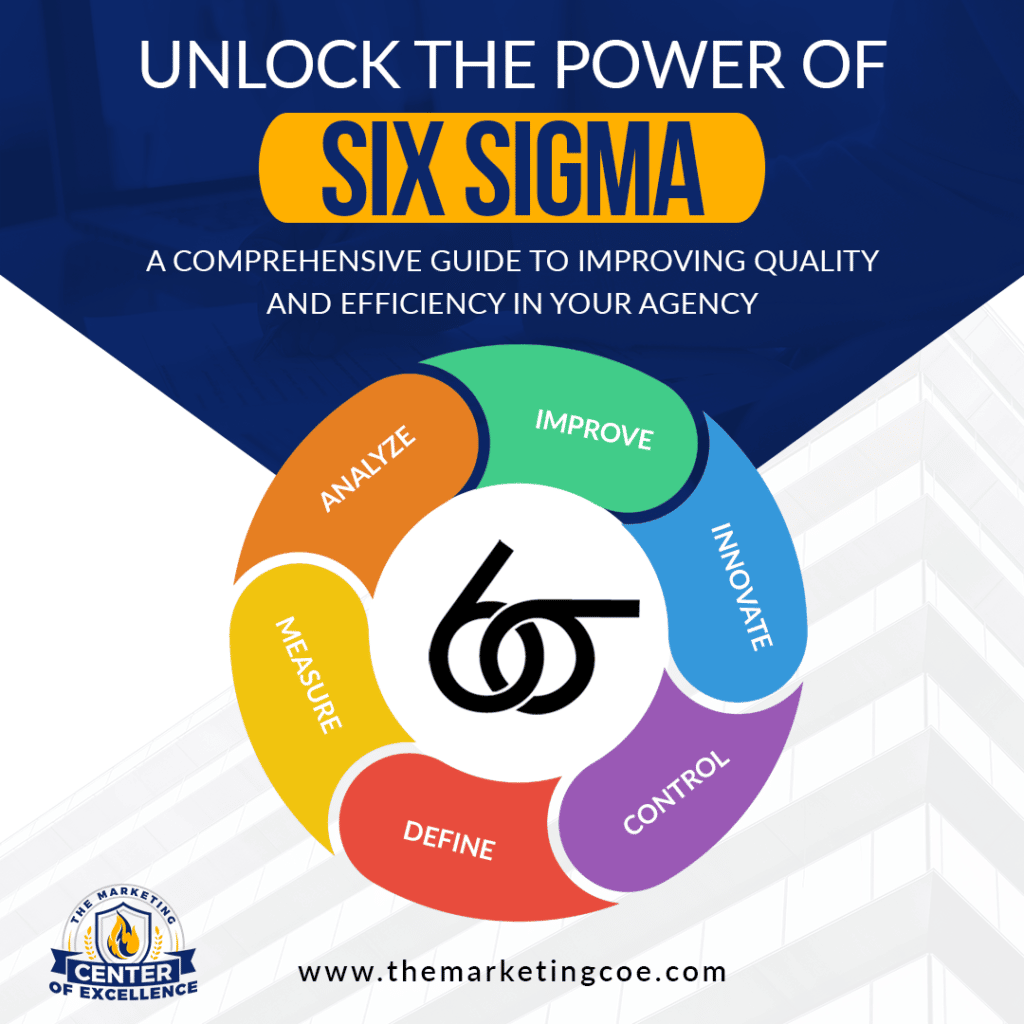

- 0.6.6 Define-Measure-Analyze-Improve-Control (DMAIC) Problem-Solving Methodology

- 0.7 The 7 QC Tools Used to Improve Business Processes

- 1 About the Author

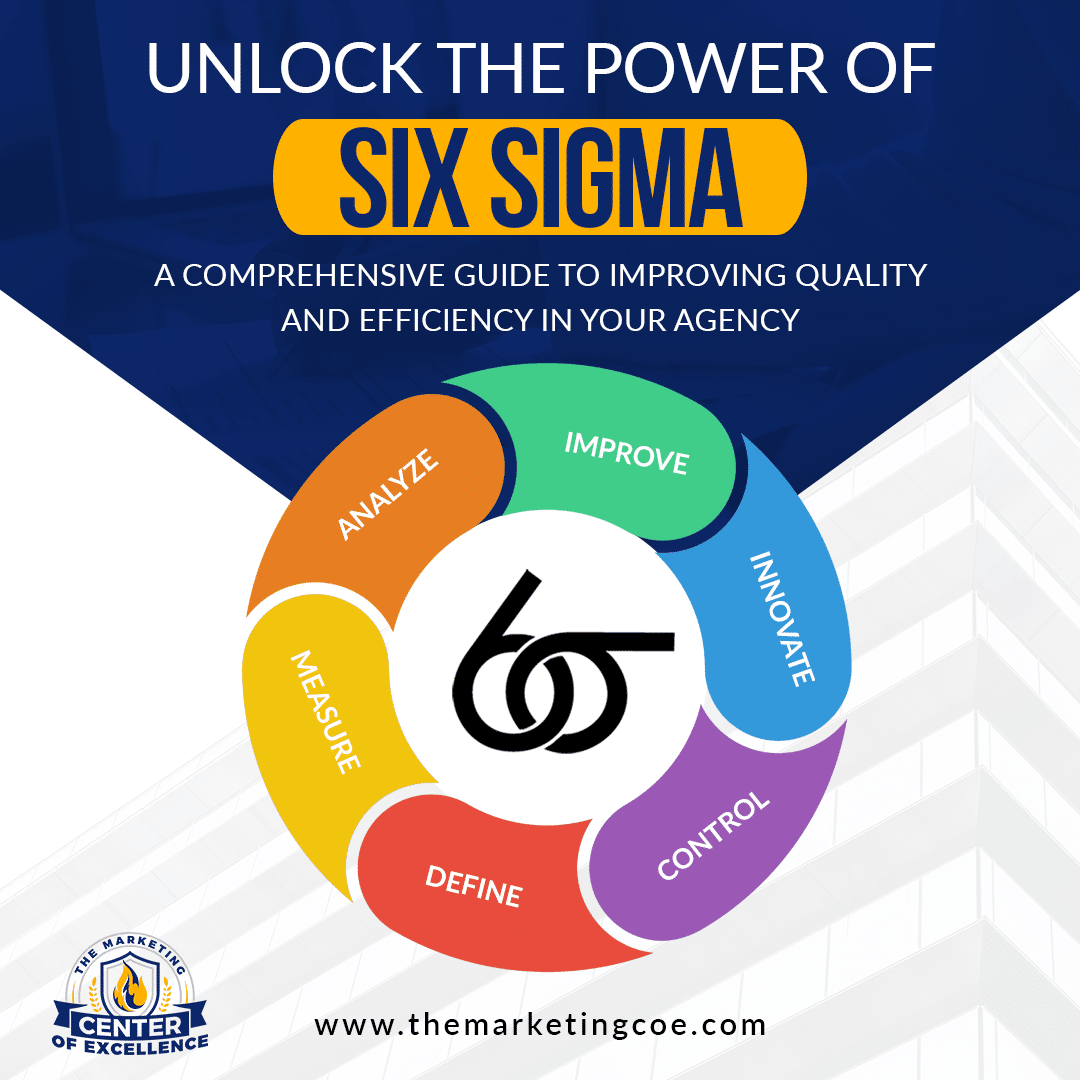

The Six Sigma Approach to Marketing Agency Excellence

Six Sigma for Marketing Agencies: This is meant to provide a fairly comprehensive resource for marketing agencies looking for ideas and resources on improving quality and predictability in your agency. There are several tools and frameworks that are listed below as well. These tools and frameworks can be utilized in different ways, at different times, for different reasons, to help team leaders create a cycle of continuous improvement.

What is Six Sigma?

In Six Sigma methodology, “sigma” is a statistical term that measures the level of variation or defects in a process. The sigma level is a measure of process capability and is used to quantify the number of defects in a process per million opportunities. The higher the sigma level, the lower the defect rate.

The term “sigma” comes from the Greek letter σ, which represents a standard deviation in statistics. In Six Sigma, the term is used to represent a process’s standard deviation and quantify the number of defects that occur within that process.

For example, a process with a sigma level of 6 would have a defect rate of 3.4 defects per million opportunities. A process with a sigma level of 3 would have a defect rate of 66,807 defects per million opportunities. By increasing the sigma level of a process, organizations can reduce defects, improve quality, and increase customer satisfaction.

Overall, sigma is an important concept in Six Sigma methodology and is used to measure the level of variation and defects in a process. By reducing variation and increasing process capability, organizations can improve the quality of their products and services and achieve long-term success.

How is Six Sigma different from the EOS approach to improvement?

Six Sigma and the EOS (Entrepreneurial Operating System) approach are both methodologies used to improve business operations, but they have some key differences.

Six Sigma is a data-driven, statistical approach to quality management and process improvement. It focuses on reducing defects and minimizing variability in processes to achieve a sigma level of 6, which corresponds to a defect rate of 3.4 defects per million opportunities. Six Sigma uses a structured problem-solving methodology, such as DMAIC, to identify the root cause of problems and develop solutions. Six Sigma is typically used in manufacturing and service industries and is popular in large corporations.

On the other hand, the EOS approach is a more holistic system for managing businesses. EOS provides a framework for setting goals, creating a vision and improving communication and collaboration within the organization. It is designed to help businesses clarify their vision, align their team, and execute plans to achieve their goals. EOS uses tools and processes, such as the “Vision Traction Organizer,” to help businesses set priorities, track progress, and ensure accountability. EOS is popular among small to mid-sized businesses, particularly in the entrepreneurial and family-owned sectors.

Six Sigma and EOS approaches have different focuses and business improvement approaches. Six Sigma focuses on improving processes and reducing defects, while EOS provides a system for setting goals, improving communication, and executing a plan. Which approach is best for a particular business depends on the business’s goals, culture, and specific challenges.

What is Lean Six Sigma?

Lean Six Sigma combines two process improvement methodologies: Lean and Six Sigma. It is a holistic approach to quality management and process optimization, which combines the principles of both Lean and Six Sigma to achieve process improvement and waste reduction.

Lean is a methodology that focuses on maximizing value and minimizing waste in a process. It emphasizes eliminating non-value-added activities and reducing cycle time to create a more efficient and responsive process.

On the other hand, Six Sigma is a data-driven approach focusing on reducing defects and minimizing variation in a process. It uses statistical analysis to identify the root cause of problems and develop solutions to address them.

Lean and Six Sigma provide a powerful approach to quality improvement and process optimization. Lean helps to identify and eliminate waste, while Six Sigma helps to reduce defects and variability in a process.

The combination of Lean and Six Sigma is often referred to as “Lean Six Sigma”. It is a disciplined and data-driven approach to process improvement, focusing on achieving process excellence, reducing costs, and increasing customer satisfaction.

Lean Six Sigma is a powerful process improvement and waste reduction methodology widely adopted in many industries. It combines the strengths of both Lean and Six Sigma, providing a holistic approach to quality management and process optimization.

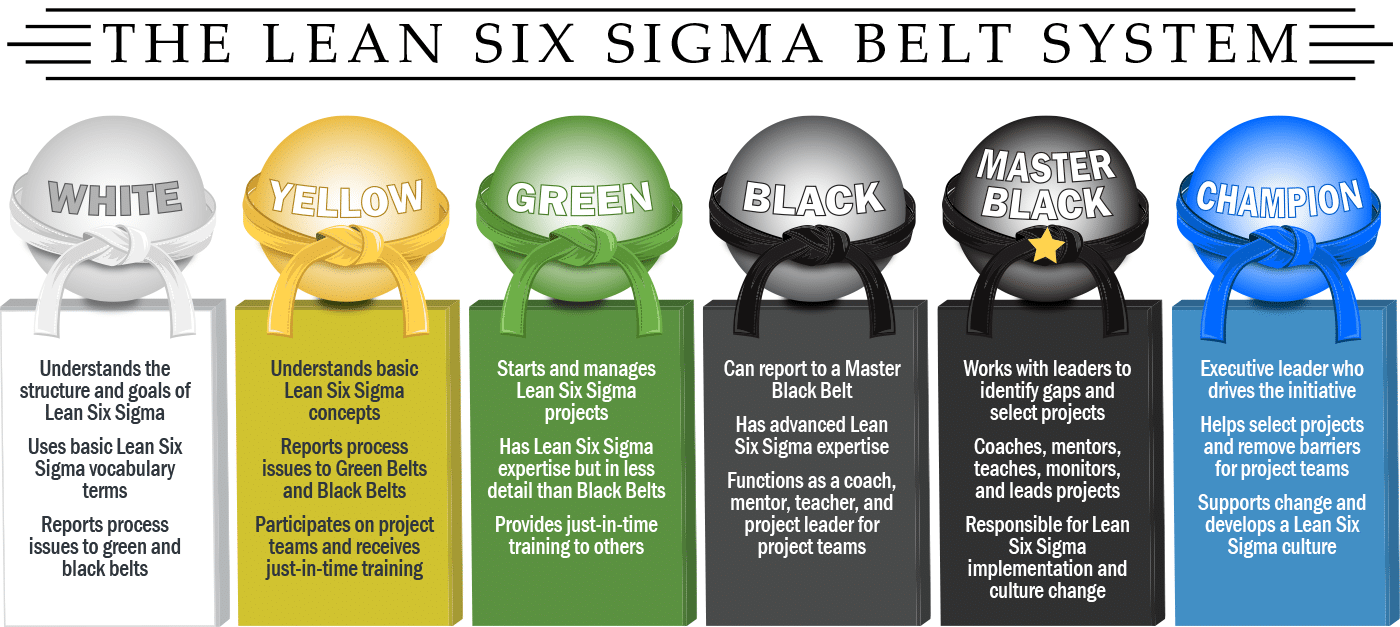

What are the belts in six sigma?

Six Sigma has different certification levels, commonly called “belts.” The Six Sigma belts are similar to the colored belts used in martial arts and indicate the practitioner’s level of expertise and training.

The Six Sigma belts and their corresponding levels of certification:

- White Belt: This is the introductory level of Six Sigma certification, which provides a basic understanding of the principles and methodology of Six Sigma. It is typically a short training course introducing Six Sigma’s key concepts and tools.

- Yellow Belt: Yellow Belt training provides a more detailed understanding of Six Sigma methodology, tools and techniques and how they can be applied to improve processes. Yellow Belt holders often work as team members on Six Sigma projects.

- Green Belt: Green Belt certification provides higher training in Six Sigma methodology and statistical tools. Green Belt holders lead Six Sigma projects and may coach and mentor other team members.

- Black Belt: Black Belt certification provides an in-depth understanding of Six Sigma methodology, statistical analysis, and project management. Black Belt holders are responsible for leading and managing Six Sigma projects within their organization and are often involved in strategic planning and business improvement.

- Master Black Belt: This is the highest level of Six Sigma certification reserved for experts in Six Sigma methodology and training. Master Black Belt holders are responsible for training and coaching Black Belts and Green Belts and for leading and managing multiple Six Sigma projects within their organization.

The Six Sigma belt system provides a structured approach to training and certification in Six Sigma methodology and tools. It allows individuals to develop their skills and expertise in Six Sigma and to apply them to improve processes and drive business improvement.

The definitive guide to implementing Six Sigma into your agency business:

- Understand the principles of Six Sigma: Six Sigma is a data-driven, problem-solving methodology that focuses on reducing defects and variability in processes. It is based on the principles of continuous improvement and uses a structured approach to problem-solving.

- Develop a Six Sigma program: Develop a Six Sigma program tailored to your business’s needs. This involves selecting team members, defining the program’s scope, and setting goals and objectives.

- Identify projects suitable for Six Sigma based on their impact on the business and their potential for improvement. This involves prioritizing projects based on their importance to the organization and selecting those most likely to provide significant benefits.

- Define the problem: Clearly define the problem or issue that needs to be addressed. This involves gathering information about the situation, including the symptoms and the impact on the organization.

- Use the DMAIC cycle: Use the DMAIC cycle to guide the problem-solving process. This involves defining the problem, measuring the current process performance, analyzing the data, improving the process, and controlling the improvements to ensure they are sustained.

- Standardize processes: Use Six Sigma to standardize processes and reduce variability. This involves identifying the best practices and methods proven to work and creating a process manual outlining the procedures involved in each process step.

- Develop a continuous improvement mindset: Foster a culture of continuous improvement by encouraging team members to identify areas for improvement and find ways to streamline processes. This approach can drive long-term success and ensure that the organization continuously strives to improve.

- Use Six Sigma tools and techniques: Use Six Sigma tools and techniques, such as statistical analysis, process mapping, and root cause analysis, to identify and address problems. These tools can ensure that decisions are based on facts and data rather than assumptions or opinions.

- Measure and track performance: Measure and track the performance of the process to ensure that the improvements are sustained. This involves tracking key performance indicators, such as cycle time, lead time, and defect rates.

- Train and support team members: Train and support team members to ensure that they understand the principles of Six Sigma and how to apply them in their work. This involves providing training and support to ensure everyone understands the procedures involved.

By following these steps, your organization can successfully implement Six Sigma and improve the quality of its products and services, reduce defects, and increase customer satisfaction. Six Sigma is a proven methodology for driving continuous improvement and achieving long-term success.

To help teams define and standardize processes, here are some key strategies:

- Identify the key steps: Start by identifying the key steps in your processes. This involves mapping out the process, from beginning to end, to identify the individual steps involved. This will help you to understand the process flow and to identify any areas that can be improved.

- Standardize procedures: Once you have identified the key steps, standardize the procedures involved. This involves creating a step-by-step guide outlining each step’s procedures. This will help ensure consistency and reduce errors.

- Document processes: Documenting your processes ensures consistency and reduces errors. This involves creating a process manual outlining each step’s procedures. The manual should be clear, concise, and easy to follow.

- Communicate processes: Communicating your processes to your team is critical to ensure everyone understands the procedures involved. This involves providing training and support to your team to ensure they are comfortable with the procedures involved.

- Track performance: Once the processes are in place, track the performance of the processes to identify areas of improvement. This involves monitoring the performance of the process and collecting data to measure its effectiveness.

- Continuous improvement: Implement a continuous improvement mindset and encourage your team to identify areas of improvement and find ways to streamline processes. This approach can foster a continuous improvement culture and drive long-term success.

Some expert secrets to help teams standardize processes include:

- Use a visual approach: Use visuals, such as process maps or flowcharts, to help team members understand the process and to identify areas for improvement.

- Involve the team: Involve team members in the standardization process, and encourage their input and feedback. This can help to ensure that the standards are practical and feasible and that everyone understands and supports the procedures involved.

- Standardize inputs and outputs: Standardize the inputs and outputs of the process to ensure consistency and reduce errors. This can involve using templates, checklists, or other tools to ensure that inputs and outputs are consistent and meet the standards.

To help teams map the customer journey, here are some key strategies:

- Identify customer touchpoints: Identify the various touchpoints where customers interact with your organization. These touchpoints could include your website, social media channels, customer service, sales representatives, and more.

- Collect customer feedback: Collect customer feedback at each touchpoint to understand their needs and expectations. This can be done through surveys, reviews, or direct feedback from customer service representatives.

- Create customer personas: Develop customer personas representing the various types of customers interacting with your organization. This will help you understand your customers’ needs, preferences, and expectations.

- Map the customer journey: Map out the customer journey from the customer’s perspective, starting with their initial awareness of your organization and ending with their post-purchase experience. This will help you to understand the different touchpoints and interactions that customers have with your organization.

- Identify pain points: In the customer journey, customers may experience frustration or dissatisfaction. This will help you to understand the areas that need improvement.

- Develop solutions: Develop solutions to address the pain points in the customer journey. This could include improving customer service, simplifying the ordering process, or offering personalized experiences.

- Test and refine: Test the solutions you have developed and refine them based on customer feedback. This will help you to improve the customer experience continuously.

By following these strategies, your team can better understand the customer journey and identify areas where improvements can be made to enhance the customer experience.

Teams can identify waste in their processes by following these steps:

- Identify the key steps: Identify the critical steps involved in the process, from beginning to end. This will help you to understand the process flow and identify areas that may be causing waste.

- Define waste: Define the types of waste relevant to your process. The eight types of waste are defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and excess processing.

- Analyze the process: Analyze the process to identify areas where waste may occur. This can be done by observing the process, gathering data, or conducting a process review.

- Measure performance: Measure the performance of the process to identify areas where waste occurs. This involves tracking key performance indicators like cycle time, lead time, and defect rates.

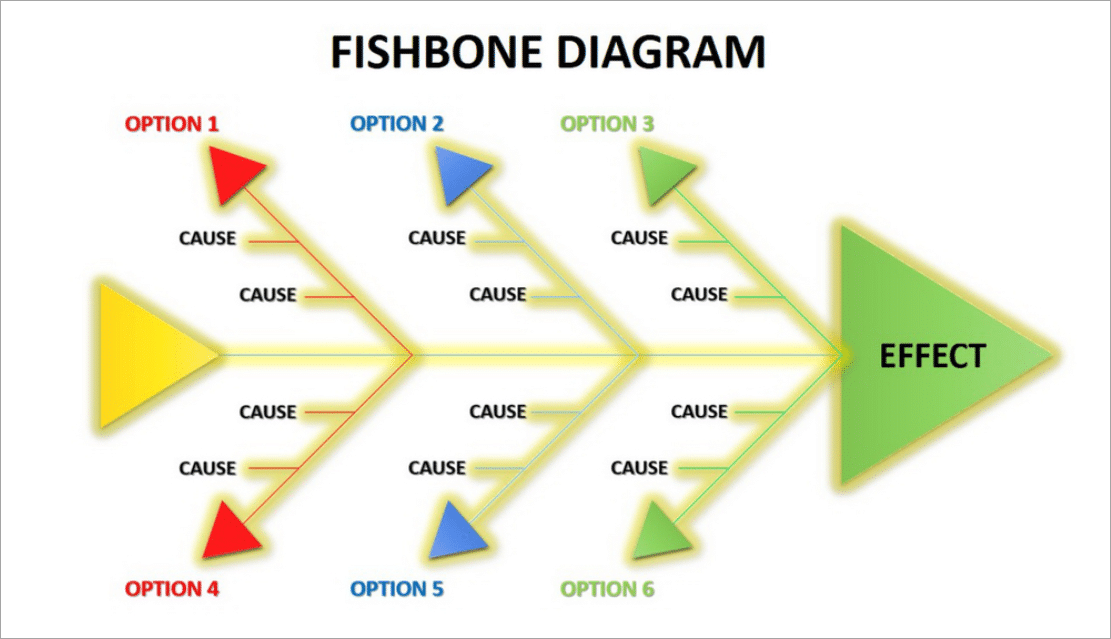

- Identify root causes: Identify the root causes of waste in the process. This can be done using root cause analysis or fishbone diagrams.

- Develop solutions: Develop solutions to eliminate or reduce waste in the process. This could include process improvements, standardization, automation, or better resource utilization.

- Implement improvements: Implement the improvements and track the results. This will help you determine whether the changes have effectively reduced waste.

By following these steps, teams can identify waste in their processes and develop solutions to improve efficiency and reduce waste.

Root cause analysis (RCA) is a problem-solving technique used to identify the underlying causes of a problem or issue. RCA aims to identify the root cause of a problem rather than treat the symptoms. By identifying the root cause, organizations can develop more effective solutions and prevent the problem from recurring.

Here is a framework for conducting Root Cause Analysis (RCA):

- Define the problem: Clearly define the problem or issue that needs to be addressed. This involves gathering information about the problem, including the symptoms and the impact on the organization.

- Collect data: Gather data about the problem to identify the underlying causes. This can be done by collecting data through observations, interviews, surveys, or other means.

- Identify contributing factors: Identify the contributing factors leading to the problem. This involves analyzing the data collected to identify the factors contributing to the problem.

- Identify the root cause: Identify the underlying root cause of the problem. This involves analyzing the contributing factors to identify the root cause of the problem.

- Develop solutions: Develop solutions to address the root cause of the problem. This involves brainstorming and evaluating potential solutions that address the root cause.

- Implement solutions: Implement the solutions and monitor the results. This involves implementing the identified solutions and tracking the results to ensure the problem is resolved.

- Prevent recurrence: Take steps to prevent the problem from recurring. This involves identifying and implementing preventive measures to prevent the root cause from reoccurring and implementing preventive measures.

By following this framework, teams can identify the root cause of a problem and develop practical solutions to prevent it from recurring. The RCA process can help organizations to continuously improve and prevent problems from affecting their operations.

Plan-Do-Check-Act (PDCA) Methodology to Solving Problems

Plan-Do-Check-Act (PDCA) is a problem-solving methodology and continuous improvement framework used in many industries, including manufacturing, healthcare, and service. The PDCA cycle consists of four stages: Plan, Do, Check, and Act. These stages are repeated in a continuous loop, allowing for continuous improvement of processes and products.

- Plan: In the first stage of the PDCA cycle, the problem or issue is defined, and goals and objectives are established. This involves identifying the problem, gathering data, and analyzing the data to determine the root cause of the problem. Based on this information, a plan is developed to address the problem and achieve the goals and objectives.

- Do: In the second stage of the PDCA cycle, the plan is implemented. This involves implementing the plan and testing the changes to the process or product. Data is collected during this stage to measure the effectiveness of the plan.

- Check: In the third stage of the PDCA cycle, the data collected in the previous stage is analyzed. This involves comparing the data to the goals and objectives established in the first stage. The data analysis determines whether the plan effectively addresses the problem and achieves the goals and objectives.

- Act: In the fourth stage of the PDCA cycle, the analysis results are used to make improvements. If the plan is successful, it is standardized and incorporated into the process. If the plan is unsuccessful, the process is repeated, and a new plan is developed to address the problem.

The PDCA cycle is repeated continuously, allowing for constant improvement of the process or product. Organizations can identify and address problems systematically and effectively by following the PDCA cycle. The PDCA cycle provides a structured approach to problem-solving and continuous improvement, allowing organizations to achieve better results and improve their operations over time.

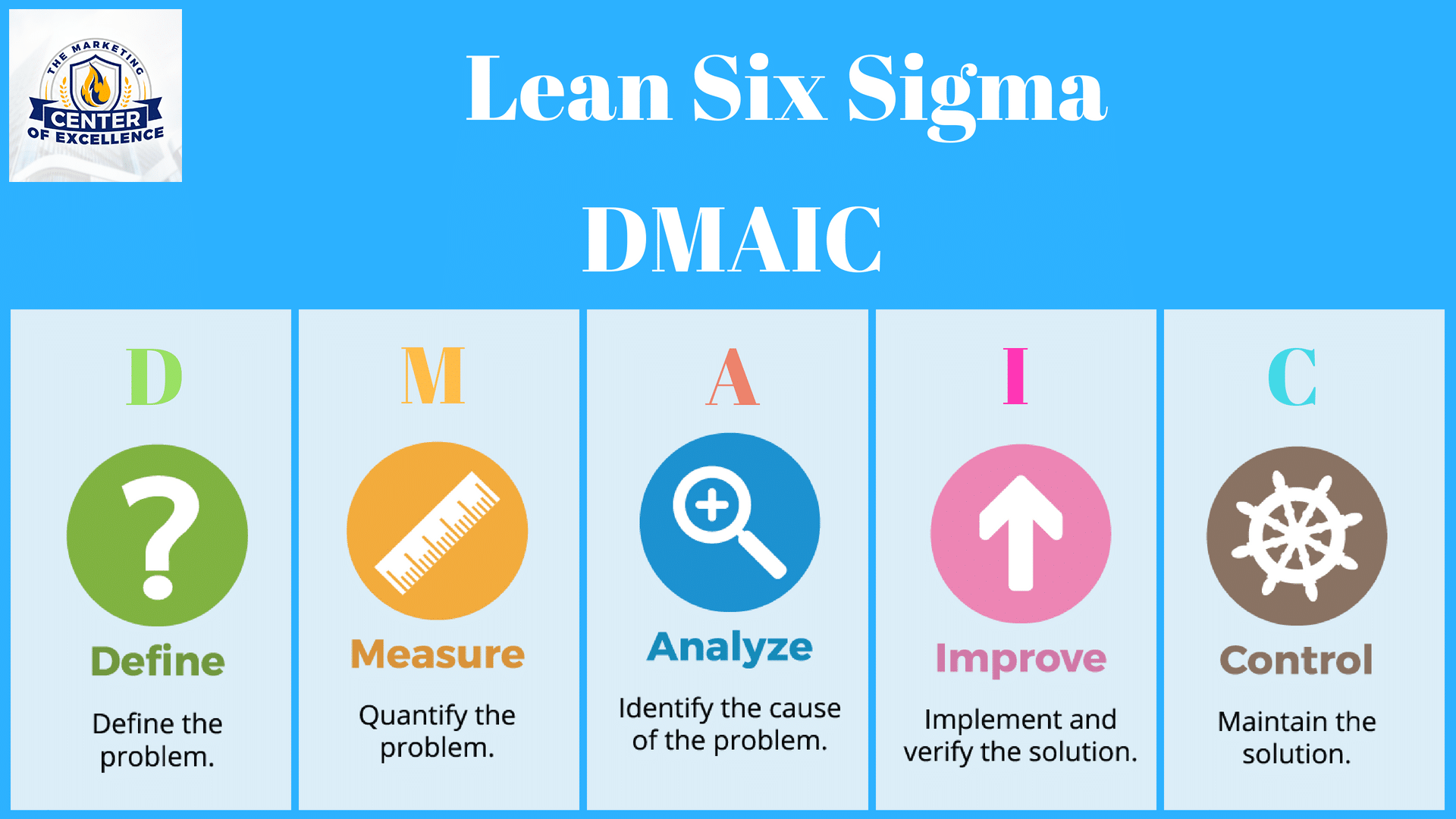

Define-Measure-Analyze-Improve-Control (DMAIC) Problem-Solving Methodology

Define-Measure-Analyze-Improve-Control (DMAIC) is a problem-solving methodology used in Six Sigma for process improvement. DMAIC is a data-driven approach for improving quality and reducing defects by following a structured problem-solving framework.

The DMAIC cycle consists of five stages: Define, Measure, Analyze, Improve, and Control.

- Define: In the first stage of the DMAIC cycle, the problem or issue is defined, and the project goals and objectives are established. This involves identifying the problem, gathering data, and defining the project’s scope. A project charter is created, which outlines the problem, goals, scope, and team members.

- Measure: In the second stage of the DMAIC cycle, data is collected to measure the current process performance. This involves identifying the key process inputs and outputs and collecting data on the performance. This data creates a process map and establishes the process’s baseline performance.

- Analyze: In the third stage of the DMAIC cycle, the data collected in the previous stage is analyzed to identify the root cause of the problem. This involves using statistical tools to analyze the data and identify the variables contributing to the problem. The root cause of the problem is identified, and potential solutions are developed.

- Improve: In the fourth stage of the DMAIC cycle, the potential solutions developed in the previous stage are tested and implemented. This involves testing the solutions in a controlled environment and measuring the results. The best solution is selected and implemented into the process.

- Control: In the fifth stage of the DMAIC cycle, the improvements made in the previous stage are monitored and controlled to ensure they are sustained. This involves implementing control measures to prevent the recurring problem and ensure that the process continues to perform at a high level.

The DMAIC cycle is a structured approach to problem-solving that provides a framework for continuous improvement. By following the DMAIC cycle, organizations can improve quality, reduce defects, and increase efficiency. The DMAIC cycle is a data-driven approach, which ensures that decisions are based on facts and data, rather than assumptions or opinions.

Following these strategies and expert secrets, teams can standardize processes, improve efficiency, and reduce errors. This helps create a more streamlined and effective organization with higher quality and customer satisfaction.

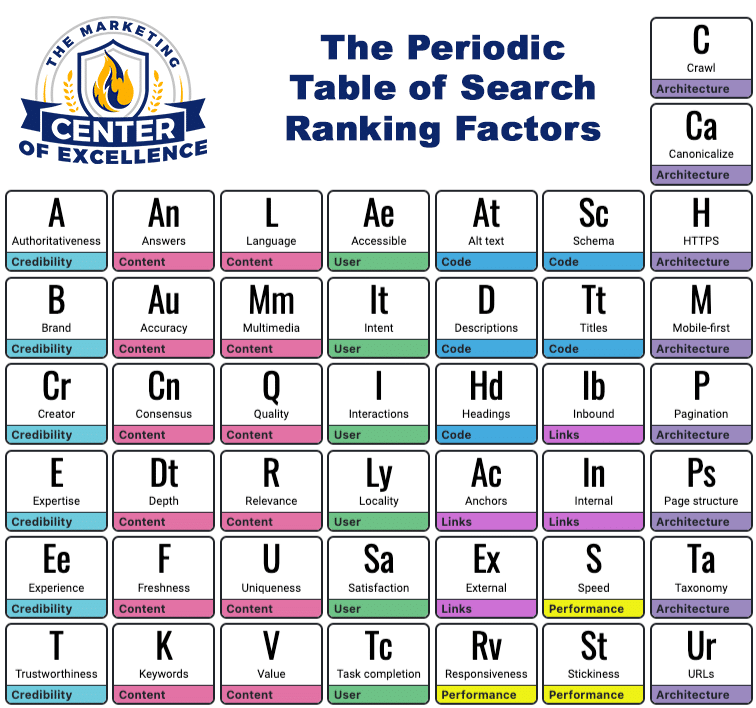

The 7 QC Tools Used to Improve Business Processes

The seven basic quality tools are fundamental tools and techniques quality management professionals use to improve business processes. These tools are also known as the “7 QC Tools”

The tools are:

- Check Sheet: A check sheet is a simple tool used to gather data and track the frequency of a particular event. Check sheets can be used to identify patterns and trends in data.

- Control Chart: A control chart is a graph that tracks process data over time. It is used to monitor the stability of a process and detect any changes or trends that could indicate a problem.

- Histogram: A histogram is a bar chart showing a data set’s frequency distribution. It is used to analyze data and identify any patterns or trends.

- Pareto Chart: A Pareto chart is a bar chart that shows the relative frequency or size of problems in a process. It is used to identify and prioritize the most significant problems for improvement.

- Scatter Diagram: A scatter diagram is a graph that shows the relationship between two variables. It is used to identify any correlations or patterns between the variables.

- Flowchart: A flowchart is a diagram that shows the sequence of steps in a process. It is used to identify inefficiencies and opportunities for improvement in a process.

- Fishbone Diagram: A fishbone diagram is also known as an Ishikawa or cause-and-effect diagram. It is used to identify the potential causes of a problem or issue and to organize the causes into categories. It helps to understand the root cause and develop solutions to address it.

Overall, these seven basic quality tools are essential to quality management professionals in identifying problems, analyzing data, and improving their organization’s processes.

I hope you find this Comprehensive Guide to Implementing Six Sigma into your agency helpful and useful, but most importantly, impactful as you implement these best practices into your own agency business. Pursuing excellence in everything that we do as business owners is a hallmark of great companies but you must have processes and systems in places to improve quality in a continuous manner. This cycle of excellence must be purposefully ingrained into your company culture.